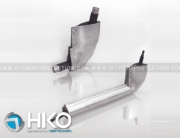

When it comes to insulating turbochargers, the HKO Heat Protection Group has developed special 3D molded parts that offer thermal insulation, acoustic absorption and vibration resistance – all of them are non-toxic insulation. Our turbocharger insulation are widely used for passenger cars, heavy-duty trucks, vessel engines, fire-pump engines, generators, biomass engines, and non-road engines. Regardless of the particular challenge, we work together with our customer s to identify the right solutions.

Our insulation using on turbocharger are:

• Temperature resistance

• Media resistance

• Erosion resistance

• Vibration resistance

• Pulsation resistance

Higher temperatures on turbochargers mean that high-tech products are playing an increasingly important role. Our insulation are fully certified to meet these requirements and demands!

Fiber types and our insulation for turbocharger:

• NA – approx.700-750 °C >> Hakotherm-800 needle mat

• NT – approx. 800-850 °C >> Hakotherm-900 needle mat

• SK – approx. 1000 °C >> Hakotherm-1200 needle mat

• ST – approx. 1050 °C >> Hakotherm-1200 turbo needle mat

• SI – approx. 1100 °C >> Hakotherm-1300 needle mat