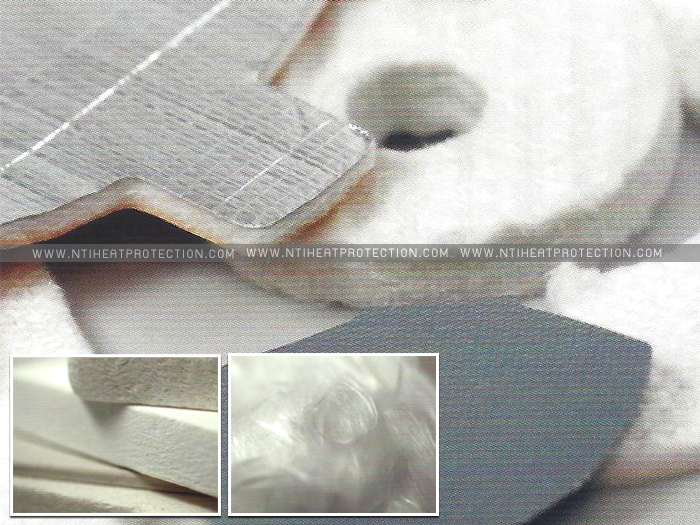

1. Needle stitch-bonded mats

– temperature resistance from 550-1,100 °C

– Thermo E-glass, type NGME

– Hakotherm®-800, type NGMA

– Hakotherm®-1200, type NGMS

– Hakotherm®-1300, type NGMI

– thickness approx. 4-12 mm

– area weight approx. 900-2,900 g/m2

– stabilized stitching using high-temperature sewing threads

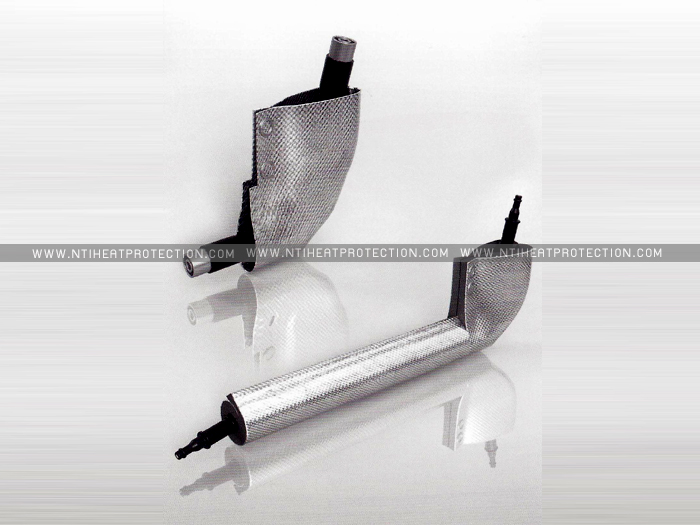

2. Molded parts as 3D parts and tubular sleeves

– temperature resistance from 550-1,100 °C

– made of Thermo E-glass, Hakotherm®-800, Hakotherm®-1200, Hakotherm®-1200 Turbo, and Hakotherm®-1300

– 3D molded parts constructed from vibration-resistant needle mats

– produced using inorganic bonding agent

3. Stamped parts

– temperature resistance from 550-1,100 °C

– Two-dimensional shapes

– Stamped, made of Thermo E-glass, Hakotherm®-800, Hakotherm®-1200, and Hakotherm®-1300

– available with self-adhesive treatments to aid in assembly

4. Custom built products

– Lamination of fabrics and needle mats with aluminium foil, stainless steel foil, or self-adhesive treatment

– Lamination of needle mats with various fabrics

– Hybrid mat manufactured from different materials

5. Stuffing fibers

– Made of Thermo E-glass, Hakotherm®-800, and Hakotherm®-1200

– Temperature resistance from 550-1,600 °C

6. Fiber boards

– Temperature resistance from 1,000-1,250 °C

– Hakotherm®-1200, thickness approx. 10-200 mm

– Hakoplan-1100-Bio, free of ceramic fibers (1×1 M, thickness 2-10 mm)