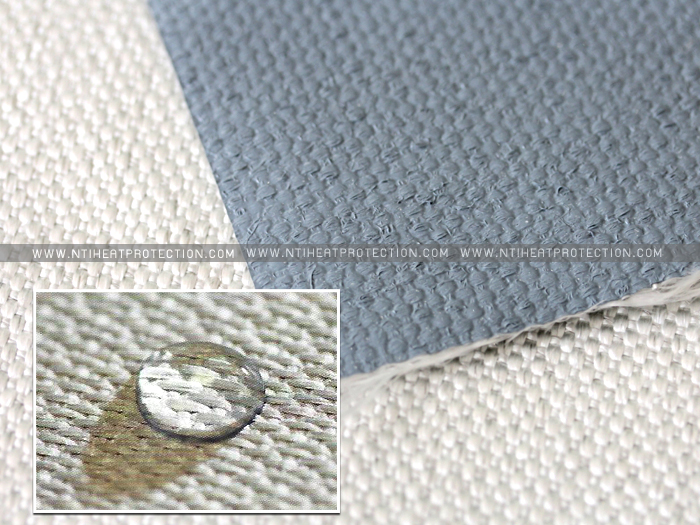

1. PTFE-coated fabrics

– one-sided/ two-sided coating based on PTFE

– excellent anti-adhesive properties

– low friction coefficient

– temperature resistance : -25 °C to +260 °C or higher in short time

– available in multiple color

– variants : static (gray), antistatic (black)

2. Standard-silicone-coated fabrics

– one-sided/ two-sided coating with silicone rubber with high load capacity even under extreme mechanical, thermal and electrical influences.

– good for light, UV, and oxidation resistance

– considerable resistance to acids and alkaline solutions, weatherproof

– good dirt-and oil-repellent effect, good electrical insulation

– temperature resistance from approx. -50 °C to +250 °C with excellent flexibility

– different color setting possible

3. Transfer-silicone-coated fabrics

– one-sided coating using the transfer process

– surface : closed or uniform, mat or glossy, smooth or structured

4. High-temperature-silicone-coated fabrics

– improved temperature resistance from approx. -50 °C to +300 °C

– short time (1 hour) to approx. +350 °C

– different color setting possible

5. Oleophobic fabrics

– impermeable to oil at room temperature for 3 months

(certified by HKO laboratory test method)

– oil resistance with grade 8 ensured on non-annealed materials

(based on AATCC 118)

– no change with respect to flammability

– olephobic properties resist organic acid concentrations common in practical applications, hard water, and commercial diesel or gasoline fuels

– long-term temperature resistance up to 200 °C (4 hours) and short-term 300 °C (1 hour)

– slight color changes possible after high temperature exposure

Applications:

• Fabrics for removable, insulation blankets (weatherproof)

• Fabric expansion joints, and fabric bellow for hydraulic tubes

• Heavy-duty welding blankets (less dust)

• Passive fireproof protection for valves and actuators

• Heat-protection and flame-retardant sleeves for electrical and controlled wires

• Energy-saving insulation jackets

Sample of fabrics:

• TG430/9KK 100/100 SR – Silicone Rubber Coated 2-Side

• TG430/9KK PTFE Antistatic – PTFE Coated 1-Side

• TG660/9A FT – Silicone Rubber Coated 1-Side

• TG1000/9L 500/500 Red – Silicone Rubber Coated 2-Side